Parametric design in AEC industry

AEC industry problems

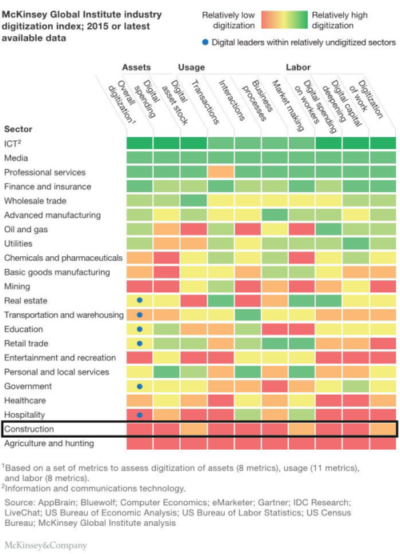

Architecture, Engineering and Construction industry is one of the least digitalized ones. Below them, there is only agriculture and hunting. This low level of digitization decreases the potential profit. The reason for low level of digitization is the fact that most of the buildings are still built on site and by relatively low educated workers. This creates a gap between the design possibilities that exist today and the construction processes. Although there is a strong tendency to move to off-site fabrication and decrease the construction impact, in order to control all these more complex production technologies, it is necessary to create a better digital connection between the design and fabrication.

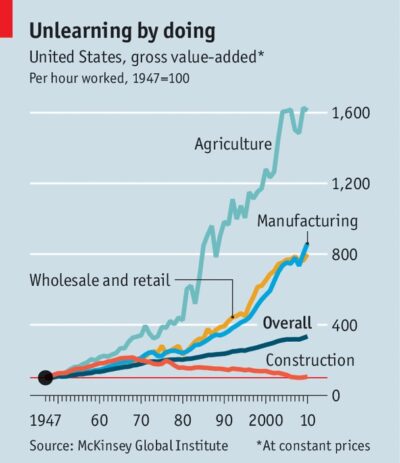

The same issue of outdated construction process is visible on the graph of productivity by different industries. There is a new mechanization available on the site, which should speed up the process, but there are also new and more complex building systems (air conditioning, maintenance equipment etc). The buildings are becoming more complex than ever, but the design and construction are remaining the same. The industries that construction industry is trying to copy are naval and aerospace engineering. Both of these moved from custom built units to modular digitally controlled production in factories.

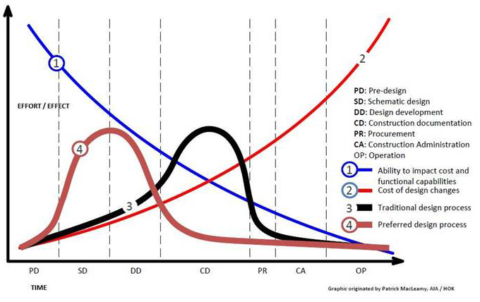

At the presented graph, the thin blue and red lines show potential impact of the design changes on the project and the cost of the changes. Their shape indicates that it is the easiest to make design changes early in the project and these changes will have the most impact and they will cost little. As the project moves forward, the changes become more expensive and there is a less possibility for impacting the final outcome. As an example, it is the easiest to change a form of the object while it is just a general model than in the later stages when most of the drawings are already prepared together with engineering elaborates (structural, mechanical, electrical etc). Changes later in the process require redoing a lot of material. The thick lines show how the changes are made in ideal case (brown) and today (black). Most of the changes today are done in the middle of the process, when the first elaborates and feedback arrive, but in that moment the possibilities to change something are decreased, so then the designers make these limited updates, but the general design is already defined. In the ideal case, early stage would also include some rough feedback and simulations, so the decisions are informed and backed by the data.

At the presented graph, the thin blue and red lines show potential impact of the design changes on the project and the cost of the changes. Their shape indicates that it is the easiest to make design changes early in the project and these changes will have the most impact and they will cost little. As the project moves forward, the changes become more expensive and there is a less possibility for impacting the final outcome. As an example, it is the easiest to change a form of the object while it is just a general model than in the later stages when most of the drawings are already prepared together with engineering elaborates (structural, mechanical, electrical etc). Changes later in the process require redoing a lot of material. The thick lines show how the changes are made in ideal case (brown) and today (black). Most of the changes today are done in the middle of the process, when the first elaborates and feedback arrive, but in that moment the possibilities to change something are decreased, so then the designers make these limited updates, but the general design is already defined. In the ideal case, early stage would also include some rough feedback and simulations, so the decisions are informed and backed by the data.

How Go Parametric helps?

The animation above shows this cyclical process of design, where the building form is defined at the beginning and the updated after each of the elaborates. Simply said, first the building form is generally defined. Then the quantity of materials is calculated, which can lead to update of the building form. Then there is a structural calculation of a new building form, which can also lead to change. Then this last version is used for energy simulation that can also bring process back to beginning if the results are not satisfactory… There are too many specific fields that impact the final solution and they are all included in the process quite late. All of this limits the design possibilities, since the architects tend to go with “safe” solutions which will require the least updates along the way. Parametric design allows inclusion of these simulations and the evaluations in the earliest stage. Through the use of algorithms it is possible to predict the building behavior in different fields. Although these predictions are not equally precise as the official elaborates, they eliminate the surprises in the later stages of the design process (or even in construction and use of the building).

With the use of algorithms it is possible to take the building through different fields and get an instant feedback on how the form impacts different aspects. Maybe slight change of certain dimensions or angles can have a big impact on the energy efficiency or structural stability, but usually these are the information that enter the process too late.

The second very useful tool used in Go Parametric design process is real time rendering. Although it is not defined as algorithmic design, it also decreases the risk of surprises when the building is already finished and brings better understanding and control of the design decisions.

How can Go Parametric help to the industry?

- Leading early stage design decisions by including all requirements from the start through algorithms

- Enabling countless iterations of the during the design process

- Providing more precise early estimates on different building factors

- Providing instant user experience and aesthetic feedback

Potential clients

Although the architectural studios are the most logical choice, the factories are the interesting one as well. In our current work, algorithms are incorporated in the design process because the membrane materials have special requirements. They must be curved in order to have maximum structural resistance. This trait is incorporated through algorithms and whichever design is produced and presented to client, it just has to be defined more precisely in later stages with minimal changes. Many new materials and building technologies have similar sort of requirements that are most easily included early. For example, curved glass is significantly more expensive than the straight one, so replacing complex curved segments with larger number of smaller but flat ones could save a lot of money. At the moment, these tools are used only in the large international companies, but there is a whole market of the firms that do not have the need for use of the algorithms all the time and could benefit from “external” parametric department.

Go Parametric examples

New Tardini stadium (2021; Parma, Italy)

Handball arena (2021; Cairo, Egypt)

Peabody’s coffee shop (2017; London, UK)